Automatic System

ds-a

Indicated for the passage of products with different specific weight, the falling flow is adjusted automatically through an electrical device.

Manual System

ds-m

Suitable for a product with multiple load points, the falling flow is manually adjusted.

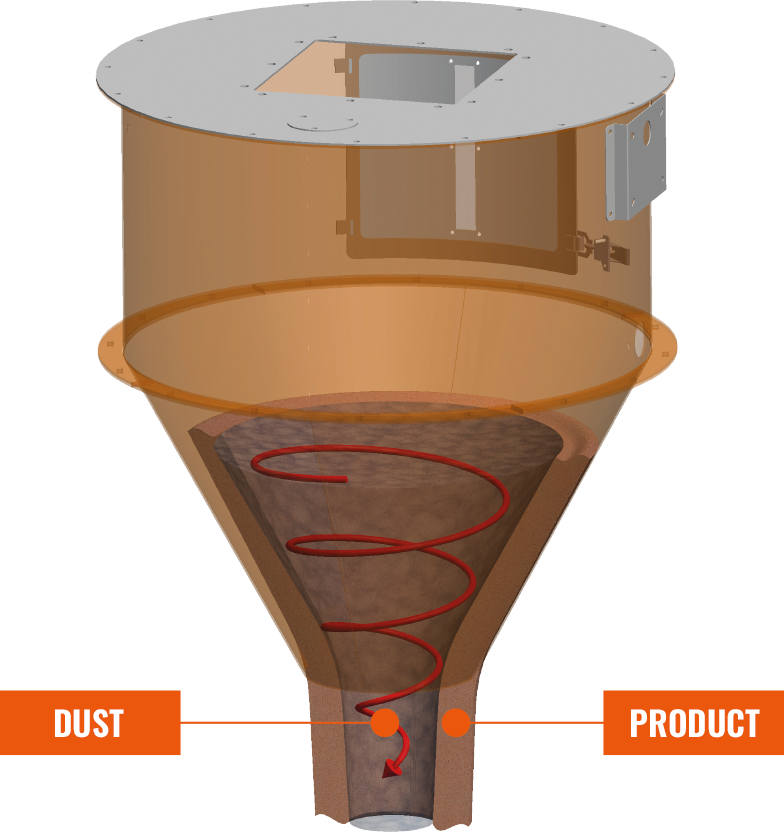

DUST STOP: hopper that stops dust and improves the environment

Dust Stop Hopper operation

The patented hopper DS - DUST STOP is available in manual and automatic modes. Both of them consist of:

- a fixed structure part, which is connected through a flange to the product feeding entrance;

- an adjustable inner part which allows to generate the vortex during its operation.

In the automatic version, the control system ofthe flow is moved and regulated by a sensor positioned on the cylinder.

The DUST STOP hopper was designed to satisfy different hourly capacities: 45 m3/h, 128 m3/h, 256 m3/h, 385 m3/h, 641 m3/h

Technical data and options

Construction

• Construction in painted carbon steel

• Product inspection window

• Bellow coupling ring

Optional

• AISI 304-316 stainless steel construction

• Bellow

• Overflow sensor

• Pneumatic damper for DS hopper movement

Details

01

Displacement pneumatic

shutter for the hopper

02

Automatic model,

sensor details

03

Electrical control

panel for DS-A